Comments from Modish

Using a Soap Shaker

(04/03/2020)

Washing dishes with a bar of soap is nothing new. Soap shakers, or soap cages, were commonly used from the 1920s to 1980s. Bars of soap, usually tallow based, were used in the wire soap cage. Small soap scraps could be added so they were not wasted.

Soap shakers went out of fashion with the manufacture of dishwashing detergents and the increase in people using dishwashing machines. Many of these synthetic detergents, although great at cleaning, are often made with toxic ingredients which many people find irritating on their skin. They are also not good for the environment, as they contain chemicals which end up in waste water systems. The other major downside with this trend, was the increase in the use of plastic packaging to store these liquid products. That’s gone even further now, with some of our powdered cleaning products also being stored in plastic containers.

So, by using a soap cage and eco-friendly hand-made natural soap, we can reduce plastics, lessen the harmful chemicals entering our eco-system, and save money for dish washing. It appears our grandparents knew best!

Read the Wikipedia soap shaker entry.

Tips for dish washing with soap bars in a shaker

(10/03/2020)

Congratulations! You’ve made the move to using a bar of dish washing soap in a soap shaker to wash the dishes. You’ve joined a growing movement that’s eco-friendly as it reduces plastics, prevents harsh chemicals going down the drain, and will likely save you money as you won’t need to use a dishwasher.

At the beginning of your new journey, you might need some time to adjust and a little perseverance may be needed.

One major difference is to understand that you are using soap, not a detergent. Chemically, these are two different things. You’re ditching the synthetic surfactants in a detergent and replacing these with natural oils in a soap formulated for cleaning. This means there are some things to consider.

Just like standing on a bar of soap in the shower, you may notice the dishes are slippery. It might take time to get used to items sliding out of your hand.

Some people may be disappointed to find their new bar of dish washing soap and new soap shaker don’t produce the bubbles expected. There can be many reasons for the lack of bubbles, one being the brand of soap you are using. Some brands cause streaks, due to their particular recipe. You can easily try a few and find one that works for you.

Water temperature can also affect the volume of bubbles produced. In general, having the water temperature as hot as possible can assist with bubble formation, hot to the point where you may need to wear gloves. Some people find washing in a large bowl placed in the sink, helps bubbles last. Keep in mind though – we have used detergent cleaners for years and have become accustomed to seeing bubbles, but, the real truth is that soap bubbles are not essential – they do not do the cleaning. The dissolved soap does the cleaning.

If you try these things and still feel you are struggling to get the dishes clean, you may live in an area prone to water hardness. Water hardness is caused by minerals leeching through limestone. If your water supply comes from such an area, it could be the hardness of your water is preventing your soap from doing its job. If your kettle is forever forming limescale inside, it’s likely you live in such an area. The good news is that most of New Zealand has soft water.

Choosing a brand of soap specifically made for dish washing and increasing the water temperature are two very simple changes you can make to get the best out of washing dishes with your vintage style soap cage or shaker.

Tips for painting MDF

Due to the building supply shortage we currently face, I have chosen to make some products such as our market display stands available in MDF. It has become more difficult and more expensive to source my preferred materials such as furniture grade plywood.

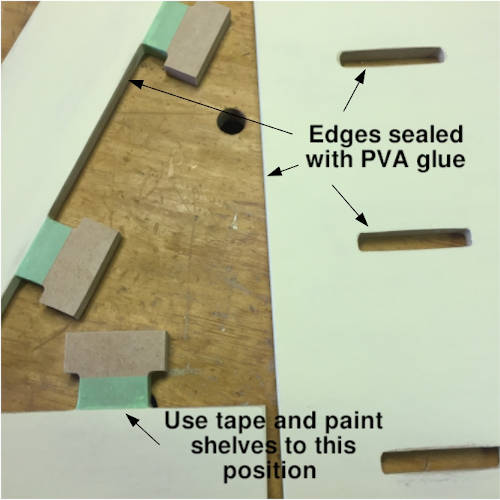

Anyway, back to the topic – painting our MDF display stands. MDF can “swell” when exposed to water. This will make it difficult to fit the shelves in to the slots in the backing board. For this reason, it is advisable to “seal” the edges of mdf with solvent based primer i.e. do NOT use a water based primer.

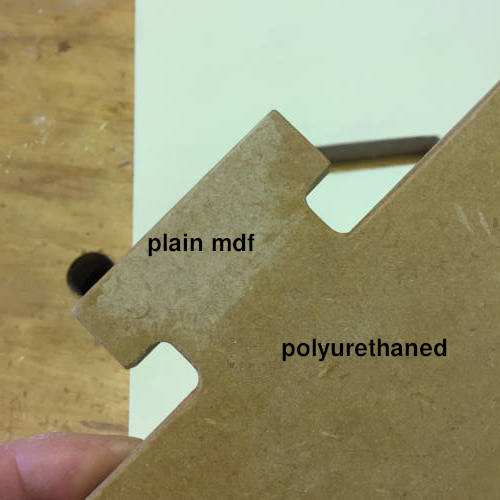

If you do not have a suitable primer to prevent the mdf edges from swelling, a cheap way (although this may not work as well as using a solvent primer) is to apply a layer of PVA glue. Allow it to dry thoroughly then apply two or three coats of paint – test pots are handy. In the one pictured I used a test pot from Resene. I applied 3 coats, with a light sanding between coats, using 220 grit sandpaper. Although this type of paint works, you will get better results using an oil based paint. If you use a test pot as discussed, I would recommend finishing this with a coat of polyurethane for extra protection and durability.

An alternative to painting is to use polyurethane – once again, do not use a water based one! This will seal and finish in two or three coats.

NB – plywood does not have these issues and also looks great finished with natural plant oils.